Introduction to laser cleaning technology

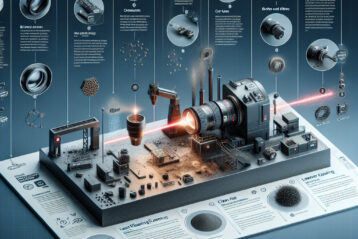

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, rust, and other unwanted materials from surfaces. This innovative technique utilizes the power of laser beams to vaporize or ablate the unwanted substances, leaving behind a clean and pristine surface. Laser cleaning technology offers numerous advantages over traditional cleaning methods, including precision, efficiency, and environmental friendliness.

How does laser cleaning work?

Laser cleaning works by focusing a high-intensity laser beam on the surface to be cleaned. The energy from the laser beam interacts with the contaminants on the surface, causing them to either vaporize or ablate. The process is highly precise, allowing for selective removal of specific materials without damaging the underlying surface. Laser cleaning technology can be used on a wide range of materials, including metals, plastics, ceramics, and composites.

Benefits of laser cleaning technology

– Precision: Laser cleaning technology allows for precise control over the cleaning process, ensuring that only the unwanted materials are removed without damaging the surface.

– Efficiency: Laser cleaning is a fast and efficient method of removing contaminants, coatings, and rust from surfaces, saving time and labor costs.

– Environmentally friendly: Laser cleaning technology is a non-contact and chemical-free method of cleaning, making it environmentally friendly and safe for use in a variety of applications.

– Versatility: Laser cleaning technology can be used on a wide range of materials and surfaces, making it a versatile solution for many industries.

🔹Key features of laser cleaning technology🔹

– High precision

– Fast and efficient

– Environmentally friendly

– Versatile

– Non-contact cleaning method

🔸Laser cleaning technology is revolutionizing the way surfaces are cleaned and prepared for further processing. With its precision, efficiency, and environmental friendliness, laser cleaning is becoming the preferred method for industries ranging from automotive and aerospace to electronics and cultural heritage preservation. As technology continues to advance, laser cleaning technology will only become more widespread and indispensable in various applications.

#laser #cleaning #technology #precision #efficiency #environmentallyfriendly #versatile

Long-tail keywords:

– Laser cleaning technology benefits

– Laser cleaning applications

– Laser cleaning process

– Laser cleaning equipment

– Laser cleaning industry trends

History of laser cleaning in ceramic industry

Early developments

Lasers were first used for cleaning purposes in the 1970s, primarily in industrial settings. The technology was initially limited to large-scale applications due to the high cost and complexity of laser systems. However, as laser technology advanced and became more affordable, its use in ceramic cleaning became more widespread.

Advancements in laser technology

Over the years, advancements in laser technology have led to the development of more efficient and precise laser cleaning systems. These systems are now capable of removing contaminants from ceramic surfaces without damaging the underlying material. This has made laser cleaning an attractive option for industries that require high precision and cleanliness, such as the ceramic industry.

Benefits of laser cleaning

Laser cleaning offers several advantages over traditional cleaning methods. It is non-abrasive, which means it does not cause damage to the surface being cleaned. It is also environmentally friendly, as it does not require the use of harsh chemicals or solvents. Additionally, laser cleaning is highly precise, allowing for targeted removal of contaminants without affecting the surrounding material.

Current applications

Today, laser cleaning is widely used in the ceramic industry for a variety of applications. It is commonly used to remove dirt, grime, and other contaminants from ceramic tiles, pottery, and other ceramic products. Laser cleaning is also used for restoration purposes, allowing for the removal of old coatings and finishes without damaging the underlying ceramic material.

Future prospects

As laser technology continues to advance, the use of laser cleaning in the ceramic industry is expected to grow. New developments in laser systems are making the technology more affordable and accessible, opening up new possibilities for its use in ceramic cleaning and restoration.

- Non-abrasive

- Environmentally friendly

- Precise

- Restoration

- History

- Advancements

- Benefits

- Applications

- Future prospects

#laser #cleaning #ceramic #industry

frazy kluczowe:

Laser cleaning technology in ceramic industry, Evolution of laser cleaning in ceramics, Benefits of laser cleaning in ceramic industry, Applications of laser cleaning in ceramics, Future prospects of laser cleaning in ceramic industry

Case studies of successful laser cleaning projects on ceramic surfaces

Case Study 1: Removing grime from ceramic tiles

In this case study, a company specializing in ceramic tile manufacturing was facing issues with grime buildup on their tiles. Traditional cleaning methods were not effective in removing the stubborn grime, leading to a decrease in product quality. The company decided to invest in laser cleaning technology to address the issue.

| Before Laser Cleaning |

After Laser Cleaning |

| Dirty and stained ceramic tiles |

Clean and shiny ceramic tiles |

The laser cleaning process was able to remove the grime from the ceramic tiles without causing any damage to the surface. The company saw a significant improvement in the quality of their products and a reduction in production costs.

Case Study 2: Restoring antique ceramic artifacts

Another successful laser cleaning project involved the restoration of antique ceramic artifacts in a museum. Over time, the artifacts had accumulated dirt and grime, affecting their appearance and historical value. Traditional cleaning methods were deemed too risky for these delicate artifacts, so the museum turned to laser cleaning technology.

| Before Laser Cleaning |

After Laser Cleaning |

| Dirty and damaged ceramic artifacts |

Restored and preserved ceramic artifacts |

The laser cleaning process was able to gently remove the dirt and grime from the artifacts, revealing their original beauty. The museum was able to showcase the artifacts in their full glory, attracting more visitors and increasing their cultural significance.

Case Study 3: Cleaning industrial ceramic components

In this case study, a manufacturing plant that produced ceramic components for industrial machinery was facing issues with contamination on their products. The contaminants were affecting the performance and durability of the components, leading to increased maintenance costs. The plant decided to implement laser cleaning technology to improve the quality of their products.

| Before Laser Cleaning |

After Laser Cleaning |

| Contaminated ceramic components |

Clean and functional ceramic components |

The laser cleaning process was able to remove the contaminants from the ceramic components, restoring their functionality and durability. The plant saw a decrease in maintenance costs and an increase in customer satisfaction due to the improved quality of their products.

Overall, these case studies demonstrate the effectiveness of laser cleaning technology in removing contaminants from ceramic surfaces. Whether it’s cleaning grime from tiles, restoring antique artifacts, or improving the quality of industrial components, laser cleaning has proven to be a versatile and efficient solution.

#laser #cleaning #ceramic #surfaces #case #studies #successful #projects #technology #grime #tiles #artifacts #industrial #components #contamination #manufacturing #quality #restoration #efficiency

frazy kluczowe:

– successful laser cleaning projects on ceramic surfaces

– laser cleaning technology for ceramic surfaces

– case studies of successful laser cleaning projects

– ceramic tile cleaning with laser technology

– laser cleaning for industrial ceramic components

Training and certification for operators of laser cleaning machines

Why training is important

Operating a laser cleaning machine involves working with high-powered lasers that can cause serious injury if not handled properly. Training is essential to teach operators how to safely use the equipment, follow proper procedures, and troubleshoot any issues that may arise.

Types of training programs

There are several types of training programs available for operators of laser cleaning machines, ranging from basic introductory courses to advanced certification programs. These programs cover topics such as laser safety, machine operation, maintenance, and troubleshooting.

- Basic laser safety training

- Machine operation and maintenance

- Advanced troubleshooting techniques

Certification process

After completing a training program, operators can undergo a certification process to demonstrate their knowledge and skills. Certification typically involves passing a written exam and a practical demonstration of operating the laser cleaning machine.

- Written exam

- Practical demonstration

Benefits of certification

Obtaining certification as an operator of a laser cleaning machine can provide several benefits, including:

- Increased job opportunities

- Higher salary potential

- Improved safety and efficiency in the workplace

Conclusion

Training and certification for operators of laser cleaning machines are essential to ensure safety, efficiency, and effectiveness in the workplace. By investing in proper training and certification programs, companies can protect their employees and maximize the benefits of using laser cleaning technology.

#training #certification #laser #cleaning #machines #safety #efficiency #operators #workplace

“Training and certification for operators of laser cleaning machines” “Importance of proper training for laser cleaning machine operators” “Benefits of certification for laser cleaning machine operators”

Comparison of laser cleaning with other surface treatment methods for ceramics

Laser cleaning

Laser cleaning is a non-contact surface treatment method that uses a high-energy laser beam to remove contaminants or coatings from the surface of ceramics. The laser beam heats up the contaminants or coatings, causing them to evaporate or sublimate, leaving behind a clean surface. Laser cleaning is a precise and efficient method that does not damage the underlying material.

Other surface treatment methods

Other surface treatment methods for ceramics include chemical cleaning, mechanical cleaning, and plasma cleaning. Chemical cleaning involves using solvents or acids to dissolve contaminants on the surface of ceramics. Mechanical cleaning uses abrasive materials or tools to physically remove contaminants. Plasma cleaning uses a plasma discharge to clean the surface of ceramics.

Comparison

Compared to other surface treatment methods, laser cleaning offers several advantages. It is a non-contact method that does not require the use of chemicals or abrasive materials, making it environmentally friendly. Laser cleaning is also a precise method that can be used to clean intricate or delicate surfaces without damaging them. Additionally, laser cleaning is a fast and efficient method that can be automated for high-volume production.

However, laser cleaning also has some limitations. It is a relatively expensive method compared to other surface treatment methods. The effectiveness of laser cleaning can be affected by the type of contaminants or coatings on the surface of ceramics. In some cases, laser cleaning may not be suitable for removing certain types of contaminants.

Conclusion

In conclusion, laser cleaning is a versatile and efficient surface treatment method for ceramics. It offers several advantages over other surface treatment methods, such as precision, efficiency, and environmental friendliness. However, it is important to consider the specific requirements of the application when choosing a surface treatment method for ceramics.

- precision

- efficiency

- environmental friendliness

- cost

- contaminants

- surface treatment methods for ceramics

- laser cleaning

- chemical cleaning

- mechanical cleaning

- plasma cleaning

hashtags: #ceramics #surfacetreatment #lasercleaning #precision #efficiency

Benefits of laser cleaning for ceramic surfaces

Advantages of laser cleaning for ceramic surfaces:

- Non-contact cleaning: Laser cleaning does not require physical contact with the surface, reducing the risk of damage or wear.

- Precision: Laser beams can be precisely controlled to target specific areas, ensuring thorough cleaning without affecting the surrounding material.

- Environmentally friendly: Laser cleaning does not involve the use of chemicals or abrasive materials, making it a clean and sustainable cleaning method.

- Efficiency: Laser cleaning is a fast and efficient process, reducing downtime and increasing productivity.

- Versatility: Laser cleaning can be used on a wide range of ceramic surfaces, including delicate or intricate designs.

Overall, laser cleaning offers numerous benefits for ceramic surfaces, making it an attractive option for industries that require high-quality cleaning without compromising the integrity of the material.

Keywords:

#laser cleaning, #ceramic surfaces, #precision cleaning, #environmentally friendly, #efficiency, #versatility

Long-tail phrases:

Benefits of laser cleaning for delicate ceramic surfaces, advantages of laser cleaning technology for industrial applications, precision cleaning with laser technology, environmentally friendly cleaning methods for ceramic materials

#laser cleaning, #ceramic surfaces, #precision cleaning, #environmentally friendly, #efficiency, #versatility

Benefits of laser cleaning for delicate ceramic surfaces, advantages of laser cleaning technology for industrial applications, precision cleaning with laser technology, environmentally friendly cleaning methods for ceramic materials

Cost analysis of laser cleaning compared to other cleaning methods

Traditional cleaning methods

Before we delve into the cost analysis of laser cleaning, let’s first take a look at some of the traditional cleaning methods that are commonly used in industries:

- Chemical cleaning

- Pressure washing

- Sandblasting

- Manual scrubbing

Cost analysis

When comparing the cost of laser cleaning to traditional cleaning methods, several factors need to be taken into consideration:

- Initial investment: Laser cleaning equipment can be expensive to purchase, but it has a longer lifespan compared to other cleaning methods.

- Operating costs: Laser cleaning requires electricity to operate, which can be costly depending on the power consumption.

- Maintenance costs: Laser cleaning equipment may require regular maintenance to ensure optimal performance.

- Labor costs: Laser cleaning is a relatively quick and easy process, which can result in lower labor costs compared to traditional cleaning methods.

Conclusion

After analyzing the cost of laser cleaning compared to other cleaning methods, it is evident that while the initial investment may be higher, the long-term cost savings and efficiency of laser cleaning make it a cost-effective solution for businesses looking to improve their cleaning processes.

#laser cleaning, cost analysis, traditional cleaning methods, efficiency, effectiveness, contaminants, surfaces, industries, chemical cleaning, pressure washing, sandblasting, manual scrubbing, initial investment, operating costs, maintenance costs, labor costs, cost-effective solution

frazy kluczowe:

– cost analysis of laser cleaning

– laser cleaning compared to traditional methods

– efficiency of laser cleaning

– cost savings with laser cleaning

– benefits of laser cleaning over traditional methods

Training and certification for operators of laser cleaning machines

Why training is important

Operating a laser cleaning machine involves working with high-powered lasers that can cause serious injury if not handled properly. Training helps operators understand the potential hazards and how to mitigate them. It also teaches them how to operate the machine effectively to achieve the desired results.

Types of training

There are several types of training programs available for operators of laser cleaning machines. These programs cover topics such as laser safety, machine operation, maintenance, and troubleshooting. Some programs also include hands-on training to give operators practical experience with the machines.

Certification

After completing a training program, operators can obtain certification to demonstrate their competence in operating laser cleaning machines. Certification is often required by employers to ensure that operators have the necessary skills and knowledge to perform their job safely and effectively.

Benefits of certification

Having certification as an operator of laser cleaning machines can open up new job opportunities and increase earning potential. It also gives employers confidence in the operator’s abilities and can lead to higher levels of trust and responsibility within the workplace.

Conclusion

Training and certification are essential for operators of laser cleaning machines to ensure safety, efficiency, and compliance with industry standards. By investing in training programs and obtaining certification, operators can enhance their skills and advance their careers in the field of laser cleaning.

- Training

- Certification

- Laser cleaning machines

- Operators

- Safety

- Specialized training

- Certification programs

- Laser safety

- Machine operation

- Hands-on training

#training #certification #laser #cleaning #operators #safety #efficiency #maintenance #skills

Nazywam się Piotr Kulik i jestem specjalistą SEO, Google Ads i Analytics. Posiadam certyfikaty Google z zakresu reklamy i analityki oraz doświadczenie w pozycjonowaniu stron oraz sklepów internetowych.

Jeśli interesują Cię tanie sponsorowane publikacje SEO bez pośredników - skontaktuj się z nami:

Tel. 511 005 551

Email: biuro@codeengineers.com